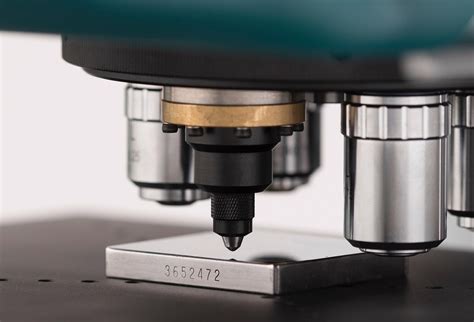

use of hardness testing in engineering|why is hardness testing important : manufacturer A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . Vazados 2023 (O retorno) 14 201 subscribers. View in Telegram. Preview channel. If you have Telegram, you can view and join Vazados 2023 .

{plog:ftitle_list}

Anúncios de acompanhantes travestis Lapa (São Paulo) Anúncios de travestis em Lapa (SP), perfis de transexuais e shemales. Travestis. Procura e publica anúncios classificados eróticos grátis em Skokka.com.

Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in manufacturing or .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .

Hardness testing holds paramount importance in materials engineering, essentially serving as the key to understanding a material's properties. It can determine the material's tensile strength, yield strength, and ductility, contributing to the manufacturing success.A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .

why is hardness testing important

Moh's Scale of hardness. Indentation testing. There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s Diamond test, and the Rockwell test. All three methods involve indentation of the material. According to the engineering regulations, the ratio of F/D 2 is 30, 10 and 2.5, which are selected according to the material hardness and sample thickness. . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended.Hardness testing is perhaps the simplest and the least expensive method of mechanically characterizing a material. This article provides an overview of the principles of hardness testing. It compares Brinell with Meyer hardness testing and hardness testing of fully cold worked metals with fully annealed metals.

runnig compression test

Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness. . There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers .ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .Scientists and engineers can use hardness testing to assess how changes in composition and processing methods will impact the hardness and hence the usability of the newly developed titanium alloy. In conclusion, the importance of hardness testing in the context of titanium alloys cannot be underestimated. It offers valuable insights into the .The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring the

types of hardness testing methods

The permanent depth of the indentation that remains is then used to calculate the Rockwell hardness number. We offer many testers at Berg Engineering which are used to measure not only Rockwell hardness, but also Brinell, Vickers, and Knoop tests. Give us a call or use our convenient online ordering to get the tester you need today. I use Vickers’ Hardness Test which can be used across different materials thereby enabling me identify material’s level of brittleness.This involves pressing the diamond pyramid indenter with square base and an angle of 136 degrees together with the opposing faces into the surface of a sample. . in engineering applications, the hardness .The Brinell Hardness Test is most typically used for testing materials that have an extremely coarse structure or when the surface is too rough for testing using another test method, such as castings and forgings.. Image Credit: Tinius Olsen. Brinell testing generally applies a very high test load (3000 kgf) with a 10 mm diameter indenter so that the indentation averages out the .

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. Why do we use engineering stress and strain? . General characteristics of hardness-testing methods and formulas for calculating hardness. Hardness Scale. The chart below is used for converting various .

The Fundamentals Of Hardness Testing In Aerospace Engineering. At the confluence of physics and engineering, hardness testing is a cornerstone of aerospace innovation. The process is foundational for determining a material’s .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually .

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

Hardness testing is a method by which the overall toughness of a material can be determined. There are several different scales that can be employed in hardness testing based on the material under examination. All of the different scales operate in the same manner. They also use the same equipment to obtain results.

Each type of hardness test offers insights into different aspects of a material’s properties. Scratch hardness is more qualitative and useful for comparative analysis in geology and gemology. Indentation hardness provides quantitative data essential for engineering and manufacturing, while rebound hardness offers a non-destructive and quick . The Rockwell test uses the depth of the impression and the Vickers test uses indentation and apical angle of 136 degrees to measure hardness, while the Knoop test is mostly used on very thin materials to determine hardness.DEPARTMENT OF MECHANICAL ENGINEERING MATERIAL TESTING LABORATORY I - CYCLE 1. Izod Test 2. Brinell Hardness Test 3. Shear Test 4. Bending Test II – CYCLE 5. Charpy Test 6. Rockwell Hardness Test 7. Torsion Test 8. Compression Test III– CYCLE 9. Heat Treatment 10. Tensile Test IV – CYCLE 11. Wear Test 12. Micro Structure Many apply a load and measure the depth or size of the resulting indentation. Hardness can be measured on the macro-, micro- or nano- scale. 1.2. Brinell Hardness Test: The oldest of the hardness testing methods in common use on engineering materials today is the Brinell hardness test, invented by Dr. J. A. Brinell in Sweden in 1900. The .

running a compression test

The Rockwell hardness test method has a whopping 30 hardness scales defined by the indenter and the two loads. A Rockwell hardness value is a combination of the numerical hardness number and the Rockwell hardness scale letters preceded by letters HR. For example, a hardness value of 70 on Rockwell scale A is written 70 HRA.The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load to a hardened sphere of a specified diameter.

This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests.

load hardness tests vs depth

running a compression test on a hemi engine

running compression engine test

19 de mai. de 2022 · Jesús and Nuria live in an apartment belonging to her father. His best hope at winning him over his is hosting an exhibition of his photography, but things do .

use of hardness testing in engineering|why is hardness testing important